Pre-commissioning Chemical Cleaning & Flushing

A Commissioning Engineers worst nightmare is when he comes across dirt and debris in the water system that they are about to commission; as he knows that the contaminated system will impede the readings and causes delays due to infrequent repeatability.

So with this said alone, there is no question! All closed circuit water systems require chemical cleaning and flushing, and here at HVAC Solutions, we are extremely conversant on how to perform this cleaning process to the latest revision of the BSRIA Application Guide.

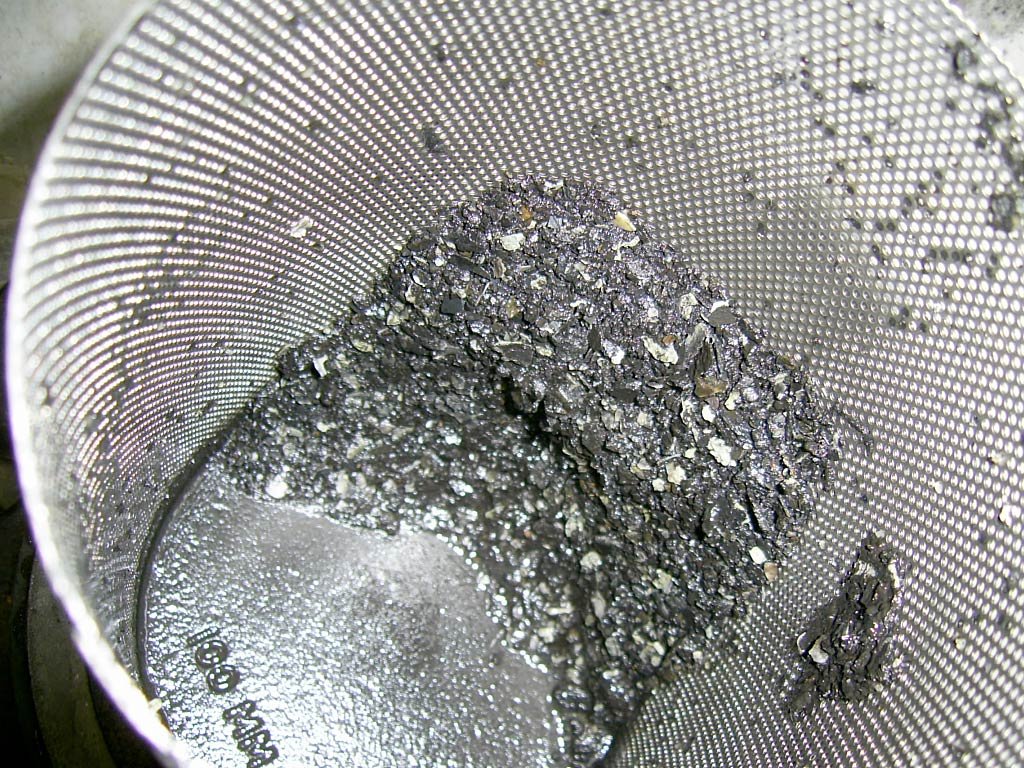

Pictured below: Blocked strainers, the third is affected by microbiological debris

Chemical Cleaning and Flushing is an international recognised pipework cleaning process and no installation in the world is impervious to dirt, following the installation of a completed system. Whether it is welding slag or surface grim; and when cleaned correctly, even copper systems and their coils give up their dirt to the process of pre-commissioning pipework cleaning.

Here at HVAC Solutions, we can help review the proposed installation and recommend the correct processes, components and facilities necessary and ultimately execute the whole process in its entirety and smooth the commissioning process that follows.

Pictured below: Strainer Debris – as found during initial drop; and then the second drop after initial dynamic flush

We believe that we are the only company in New Zealand to comprehensively conducts this pre-commissioning procedure and it is only this procedure of a proficiently cleaned system that provides a cost efficient building with fewer maintenance call outs, longer operating life and most of all; improved occupancy comfort!